Napcen Bot

We are OnlineNapcen Bot

👋 Greetings! I am Napcen Bot, at your service. How may I be of

assistance to you today?

Build with IndependentWebCrafter

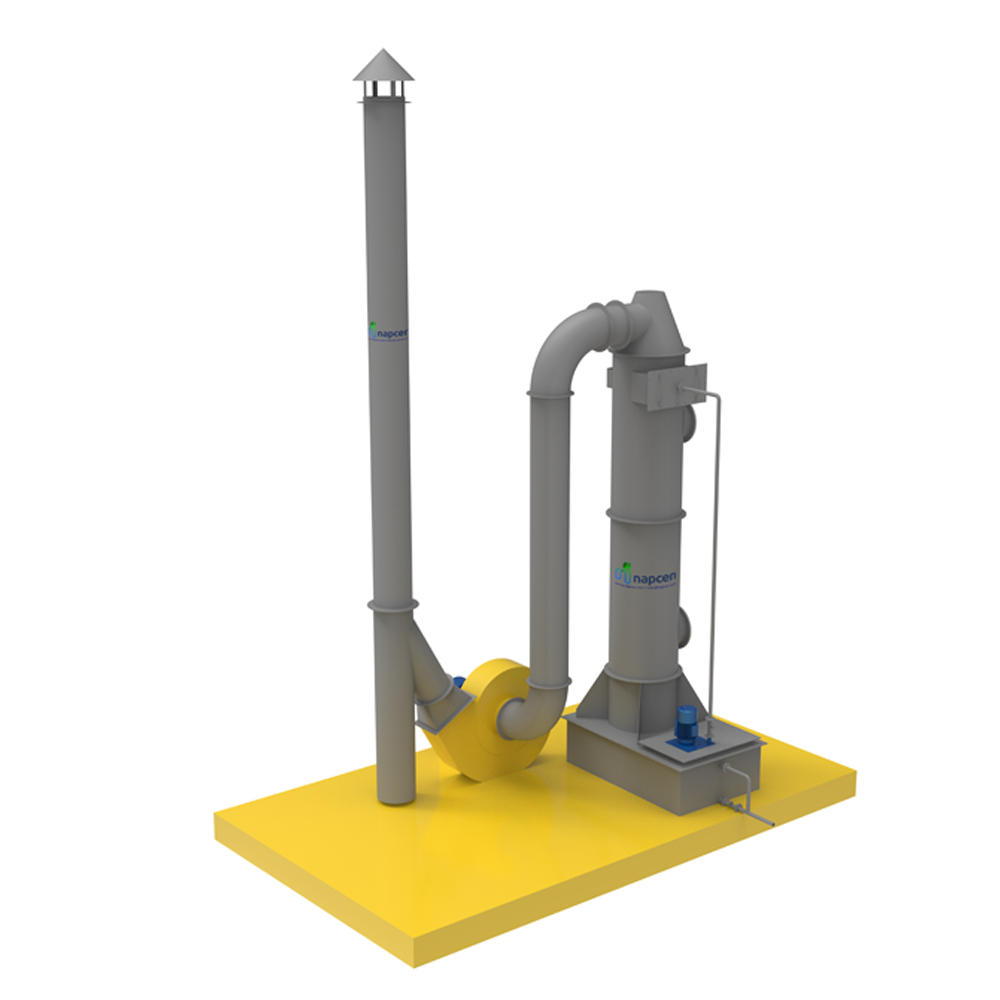

Here's how a sulfuric acid scrubber typically works:

1.Inlet: The industrial exhaust gas containing sulfur dioxide enters the scrubber system through an inlet.

2.Spray : System Inside the scrubber, there is a spray system that introduces a liquid scrubbing solution, which is typically water or a water-based solution containing alkaline substances. The scrubbing solution is distributed as a fine mist or spray.

3.Gas-Liquid Contact: The contaminated gas stream comes into contact with the scrubbing solution.

Several processes occur at this stage:

-Absorption: Sulfur dioxide gas is absorbed into the liquid phase due to chemical reactions with the alkaline components in the solution. This results in the formation of sulfite and sulfate ions.

-Neutralization: The alkaline scrubbing solution also serves to neutralize any acidic components in the gas stream.

4.Clean Gas Outlet: After passing through the scrubbing section, the treated gas exits the top of the scrubber, with significantly reduced levels of sulfur dioxide and other acid gases.

5.Liquid Collection and Treatment: The liquid scrubbing solution, now containing dissolved sulfur compounds and other impurities, is collected at the bottom of the scrubber vessel. It may undergo further treatment or be processed to recover sulfur or disposed of in accordance with environmental regulations.

Sulfuric acid scrubbers are commonly used in various industries, including:

-Power Plants: To remove sulfur dioxide emissions from flue gases generated by burning coal, oil, or natural gas.

-Smelting and Refining: In metallurgical processes, sulfuric acid scrubbers are used to capture SO2 emissions from roasting, smelting, and other operations.

-Chemical Manufacturing: To control emissions from processes that involve the production of sulfuric acid or other sulfur-containing chemicals.

-Waste Incineration: In waste-to-energy plants, sulfuric acid scrubbers help reduce SO2 emissions from the combustion of municipal solid waste.

The effectiveness of a sulfuric acid scrubber depends on factors like the design of the scrubber, the choice of scrubbing solution, and the operating conditions. Regular maintenance and monitoring are crucial to ensure that the scrubber continues to meet emission reduction goals and environmental regulations. Proper disposal or treatment of the collected liquid is also important for minimizing environmental impact.