Napcen Bot

We are OnlineNapcen Bot

👋 Greetings! I am Napcen Bot, at your service. How may I be of

assistance to you today?

Build with IndependentWebCrafter

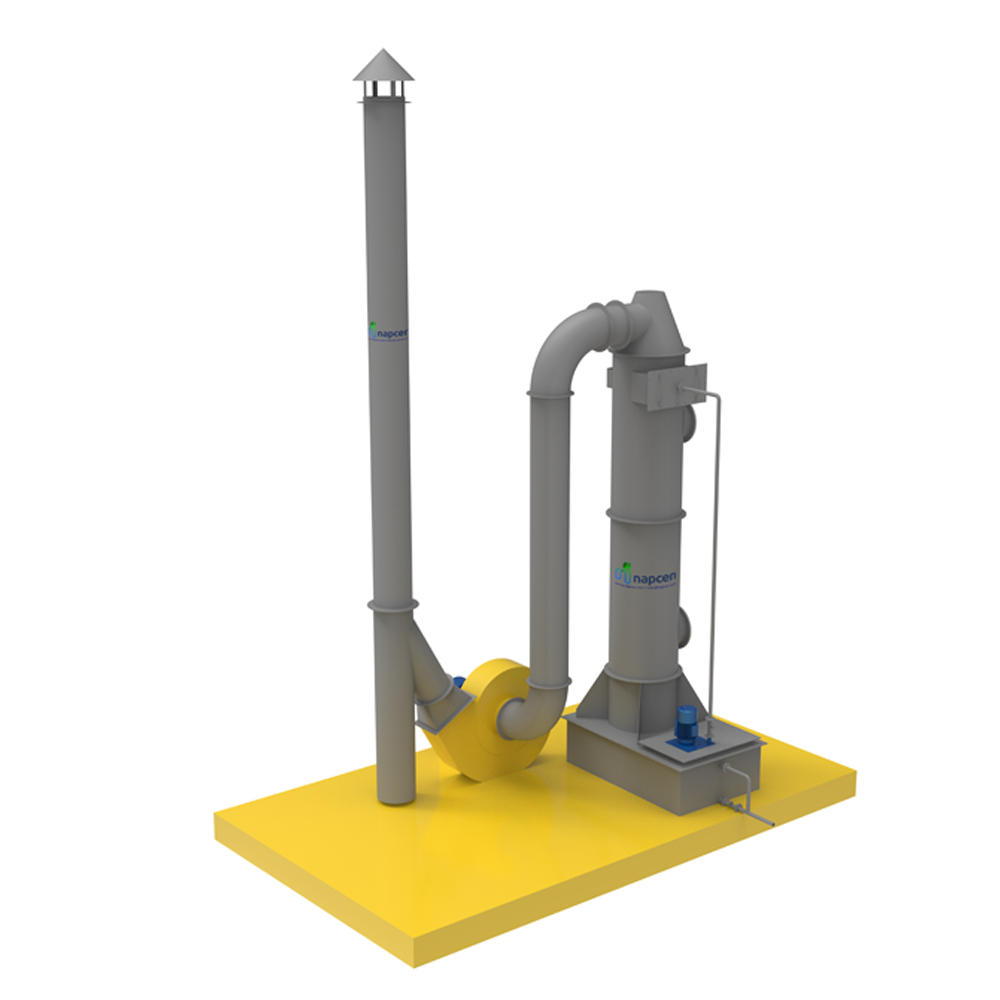

Here's how a plastic fume scrubber generally works:

1.Inlet: The polluted air is directed into the scrubber system through an inlet.

2.Contact with Scrubbing Solution: Inside the scrubber, the contaminated air comes into contact with a scrubbing solution, typically a liquid or slurry. This solution can be water or a specialized chemical solution, depending on the type of pollutants being removed.

3.Chemical Reaction: As the polluted air passes through the scrubbing solution, a chemical reaction takes place. The pollutants in the air may dissolve, react with, or otherwise be absorbed by the scrubbing solution. This process can neutralize acidic gases, remove particulate matter, or capture other harmful chemicals.

4.Separation: The Cleaned air is then separated from the scrubbing solution. This separation can occur through various mechanisms, such as mist eliminators or separation chambers.

5.Outlet: The Clean air is discharged into the atmosphere, while the scrubbing solution, now containing the captured pollutants, is collected for further treatment or disposal.

Plastic fume scrubbers are favored in certain applications due to their corrosion resistance and durability.

They are often used in industries where the exhaust gases are corrosive or contain aggressive chemicals.

The choice of plastic materials for construction depends on the specific requirements and the types of chemicals involved.

Common plastics used in the construction of these scrubbers include polypropylene (PP), polyvinyl chloride (PVC), and high-density polyethylene (HDPE). Plastic fume scrubbers find applications in various industries, including chemical manufacturing, metal processing, semiconductor fabrication, wastewater treatment, and more. They play a crucial role in reducing air pollution and protecting the environment by removing harmful emissions from industrial processes.