Napcen Bot

We are OnlineNapcen Bot

👋 Greetings! I am Napcen Bot, at your service. How may I be of

assistance to you today?

Build with IndependentWebCrafter

Here's how it works:

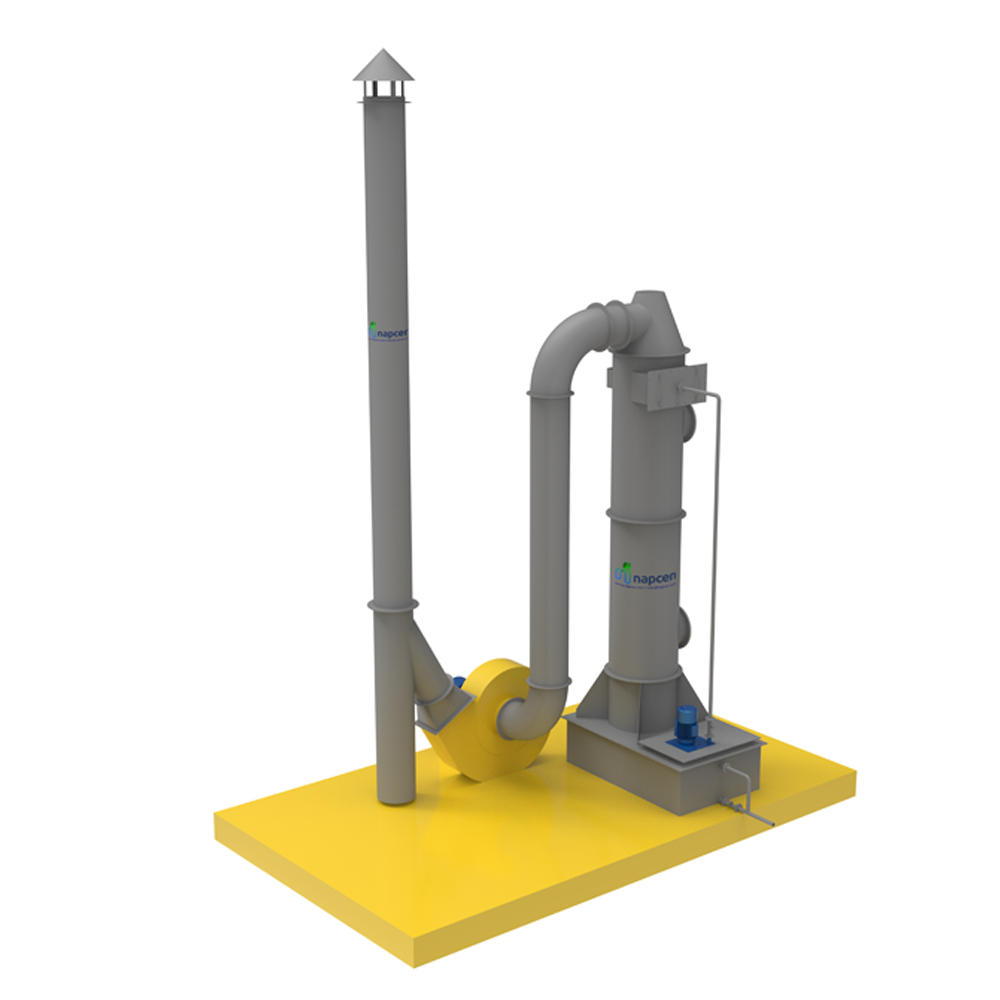

1.Venturi Tube: The core component of a Venturi scrubber is a Venturi tube. It's a constricted tube where the gas stream is accelerated to a high velocity as it passes through the narrow throat of the tube.

2.Liquid Injection: A scrubbing liquid (typically water or another suitable liquid) is injected into the Venturi tube either before or at the throat. This liquid can contain chemicals or reagents that are designed to react with and capture the pollutants in the gas stream.

3.Gas and Liquid Mixing: As the high-velocity gas flows through the Venturi tube, it creates a low-pressure area at the throat. This low-pressure area causes the liquid to be drawn into the tube and atomized into small droplets.

4.Pollutant Capture: The small liquid droplets created in the Venturi tube collide with the pollutant particles in the gas stream. This collision allows for physical absorption and chemical reactions to occur, resulting in the capture and removal of pollutants from the gas stream.

5.Clean Gas Exit: The cleaned gas, with the pollutants removed, exits the Venturi scrubber through the outlet.

Venturi scrubbers are particularly effective at removing fine particulate matter (PM), aerosols, and some gases from industrial emissions. They are often used in applications where the gas stream contains fine particulates or where wet scrubbing is necessary to control emissions. They can be found in various industries, including manufacturing, metal processing, chemical production, and more.

Advantages of Venturi scrubbers include their high particulate removal efficiency and relatively low maintenance requirements. However, they can be energy-intensive due to the high-pressure drop across the Venturi throat and may require a substantial amount of water for scrubbing, which can result in wastewater management challenges.

It's important to note that the effectiveness of a Venturi scrubber depends on several factors, including the design of the scrubber, the type of pollutants being removed, and the operating conditions. Proper design and maintenance are essential to ensure optimal performance and compliance with environmental regulations.